Predictive Maintenance becomes a factor for success for industrial businesses

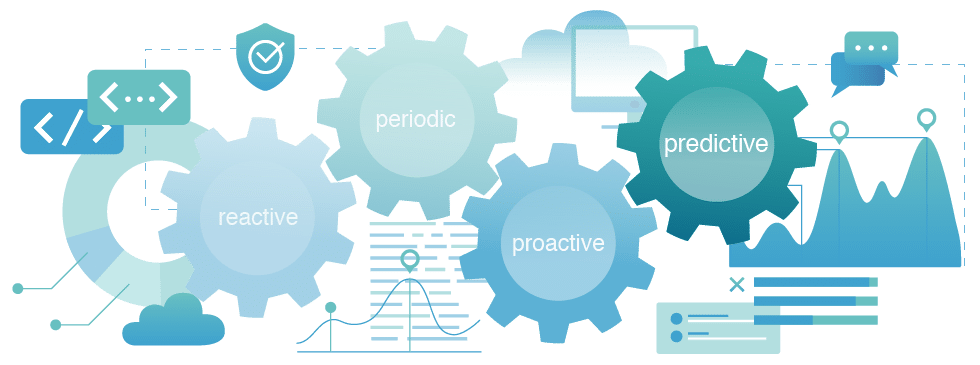

In connection with digitalization and Industry 4.0, many companies have addressed the topic of the Internet of Things (IoT). The availability of data for digital optimization has increased significantly and with it the potential to act predictively. Under the buzzword “predictive maintenance”, companies can now more reliably meet business goals through the use of sensors and monitoring solutions such as the following:

- Reduced machine and plant downtime

- Reduced maintenance and service costs

- Extended service life of machines and equipment

- Improved overall performance

- Sustainability such as energy optimization

- Increased innovation and productivity

The IoT AWS Monitron solution from copebit is an end-to-end system that includes both IoT sensors to collect vibration and temperature data and the gateway to aggregate and transmit data to AWS. The solution is rounded out by the machine learning cloud service that autonomously detects abnormal plant patterns and delivers results within minutes.

IoT AWS Monitron

- Sensors for a wide range of industrial machines (fans, generators, motors, pumps, etc.)

- Mobile app (Android and iPhone) for managing, alerting, notifying and displaying metrics

- Multi-user access with role concept for different departments

- Background based on AWS IoT and Machine Learning technologies

Our IoT AWS Monitron solution helps you proactively monitor your environment to perform predictive and planned maintenance on machines based on real-time data. For customers, this solution can be deployed without the need for experience with machine learning or the cloud.

We are happy to support you. Click here to download our IoT AWS Monitron brochure.